PRODUCTS

Contact us

Fans Lighting Company Limited

Website:www.fanslighting.com

Mail:sales@fanslighting.com

Address:No.1 Nanlong Road, Nanlian Community, Longgang District, Shenzhen 518116 China

LED strip light

LED Strip Light can be used in indoor and outdoor place, mainly used for decorating and holiday time. Energy saving up to 55% than the traditional strip light.

Features:

1. Using high quality SMD2835 LED

2. Qty of LED: 30/60/96/120 LEDs/Meter

3. Waterproof grade: IP20, IP65 Glue, IP65 Silicon Tube and IP68 Silicon Tube with Glue

4. Long life, up to 30,000+ hours

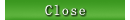

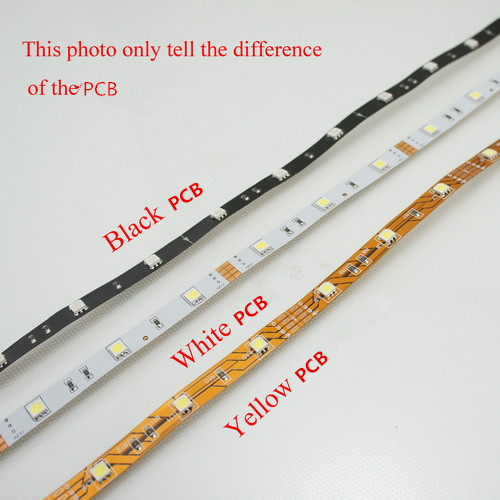

5. Color of PCB: White/Golden/Black

6. Double Sides Copper Trace Flexible PCB

7. Voltage: 12 VDC/ 24 VDC

Specification:

There are white, black and yellow PCB in available:

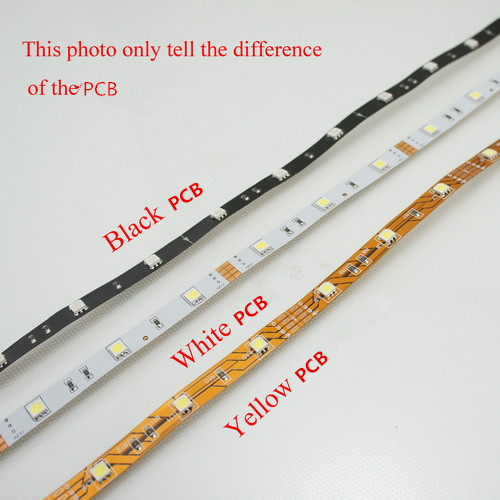

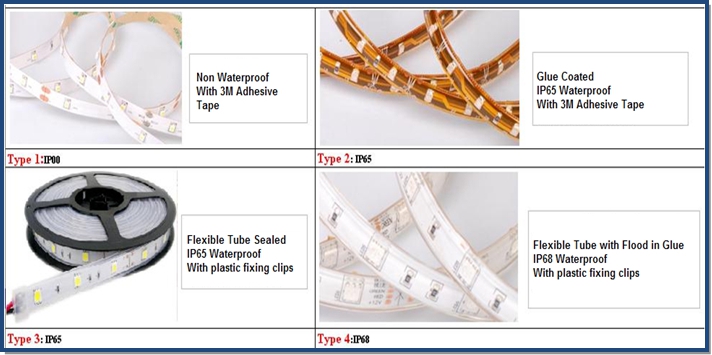

The waterproof grade as follows:

1: Non-waterproof Flexible LED Strip: PCB (Printed Circuit Board) material with self-adhesive back.

2: Waterproof Flexible LED Strip--IP65 drip glue: Except it PCB material is encapsulated with plastic Gel at surface, with self-adhesive back, Water resistant coat.

3: Waterproof Flexible LED Strip--IP65 tube coated: The PCB is enveloped by silicone tube, and with two ends sealed by gel. Without self-adhesive back. Water resistant coat.

4: Waterproof Flexible LED Strip--Whole Injection IP68: Except it PCB material is encapsulated with plastic Gel at both side. Without self-adhesive back. Water resistant coat.

Application:

1. Cove lighting Accent lighting.

2. Backlight or edge lighting for signage and channel letters.

3. DIY flexible LED strips for home use,cupboard,plinths,recesses,shelves,

wardrobe,cornie,shadow gaps,door frames, banisters hand rails,steps and patios.

4. Path and contour marking.

5. Decorative flex LED strips for holiday,event,show exhibition.

Installation:

1. Calculate length of LED strip lights.

2. Choose power supply base on the rated power and working voltage.

3. Fix LED strips lights on the mounting position.

4. Connect all LED strip lights in series or parallel.

5. Connect the display system with power supply.

Notice:

1. Each 3 LEDs could be cut for 12 VDC model and each 6 LEDs could be cut for 24 VDC model.

2. Make sure the working voltage is 12 V or 24 V DC.

3. Choose the correct IP Class model base on the application site.

4. Prohibit using LED Strip Lights without fixing.

Features:

1. Using high quality SMD2835 LED

2. Qty of LED: 30/60/96/120 LEDs/Meter

3. Waterproof grade: IP20, IP65 Glue, IP65 Silicon Tube and IP68 Silicon Tube with Glue

4. Long life, up to 30,000+ hours

5. Color of PCB: White/Golden/Black

6. Double Sides Copper Trace Flexible PCB

7. Voltage: 12 VDC/ 24 VDC

Specification:

| Model | LED type | Qty of LED/Meter | Power/Meter | Voltage | PCB width | Lumen/LED | Color |

| FS-2835-30 | SMD2835 | 30pcs | 7W | DC12/DC24V | 8mm | 20-22lm | Warm White(2700-3500K), Neutral White(4000-5000K), Cool White(6000-7000K), 7000-11000K |

| FS-2835-60 | 60pcs | 14W | |||||

| FS-2835-96 | 96pcs | 22W | |||||

| FS-2835-120 | 120pcs | 28W |

There are white, black and yellow PCB in available:

The waterproof grade as follows:

1: Non-waterproof Flexible LED Strip: PCB (Printed Circuit Board) material with self-adhesive back.

2: Waterproof Flexible LED Strip--IP65 drip glue: Except it PCB material is encapsulated with plastic Gel at surface, with self-adhesive back, Water resistant coat.

3: Waterproof Flexible LED Strip--IP65 tube coated: The PCB is enveloped by silicone tube, and with two ends sealed by gel. Without self-adhesive back. Water resistant coat.

4: Waterproof Flexible LED Strip--Whole Injection IP68: Except it PCB material is encapsulated with plastic Gel at both side. Without self-adhesive back. Water resistant coat.

Application:

1. Cove lighting Accent lighting.

2. Backlight or edge lighting for signage and channel letters.

3. DIY flexible LED strips for home use,cupboard,plinths,recesses,shelves,

wardrobe,cornie,shadow gaps,door frames, banisters hand rails,steps and patios.

4. Path and contour marking.

5. Decorative flex LED strips for holiday,event,show exhibition.

Installation:

1. Calculate length of LED strip lights.

2. Choose power supply base on the rated power and working voltage.

3. Fix LED strips lights on the mounting position.

4. Connect all LED strip lights in series or parallel.

5. Connect the display system with power supply.

Notice:

1. Each 3 LEDs could be cut for 12 VDC model and each 6 LEDs could be cut for 24 VDC model.

2. Make sure the working voltage is 12 V or 24 V DC.

3. Choose the correct IP Class model base on the application site.

4. Prohibit using LED Strip Lights without fixing.

Copyright © Fans Lighting Company Limited

No.1 Nanlong Road, Nanlian Community, Longgang District, Shenzhen 518116 China URL:www.fanslighting.com

本站部分图文来源网络,如有侵权问题请通知我们处理!

做网站维护